What is CCPS HAC and why is it important?

CCPS HAC stands for the Center for Chemical Process Safety Hazard Analysis and Critical Control.

HAC is a systematic approach to identifying, evaluating, and controlling hazards in chemical process operations. It is an important part of process safety management and can help to prevent accidents and injuries.

The HAC process typically involves the following steps:

Identifying hazards Evaluating the risks associated with each hazard Developing control measures to mitigate the risks Implementing the control measures Monitoring the effectiveness of the control measuresHAC can be used to identify and control hazards in a variety of chemical process operations, including:

Chemical manufacturingPharmaceutical manufacturingPetroleum refiningGas processingHAC is an important tool for preventing accidents and injuries in chemical process operations. By following the HAC process, companies can identify and control hazards, and reduce the risks associated with chemical process operations.

CCPS HAC

CCPS HAC, an acronym for the Center for Chemical Process Safety Hazard Analysis and Critical Control, is a systematic approach to identifying, evaluating, and controlling hazards in chemical process operations, providing a comprehensive framework for process safety management.

- Identification: Recognizing potential hazards through thorough analysis.

- Evaluation: Assessing the severity and likelihood of identified hazards.

- Mitigation: Developing and implementing measures to reduce risks associated with hazards.

- Control: Establishing and maintaining effective safeguards to prevent or minimize the impact of hazards.

- Monitoring: Regularly reviewing and updating HAC measures to ensure ongoing effectiveness.

- Communication: Sharing HAC findings and recommendations across the organization to promote awareness and collaboration.

- Continuous Improvement: Regularly evaluating and enhancing HAC processes to adapt to changing conditions and industry best practices.

These key aspects collectively contribute to the effectiveness of CCPS HAC in enhancing process safety by enabling proactive hazard management, informed decision-making, and continuous improvement. By adopting CCPS HAC principles, organizations can minimize risks, prevent incidents, and safeguard personnel, assets, and the environment.

Identification

Identifying potential hazards is a critical aspect of CCPS HAC, as it forms the foundation for effective hazard management. This involves conducting thorough and systematic analyses to recognize and understand the potential hazards associated with chemical process operations.

- Hazard Identification Techniques

CCPS HAC utilizes various hazard identification techniques, such as HAZOP (Hazard and Operability Study), FMEA (Failure Mode and Effects Analysis), and What-If analysis, to comprehensively identify potential hazards.

- Process Understanding

A deep understanding of the chemical process, its components, and their interactions is crucial for effective hazard identification. CCPS HAC emphasizes the importance of process knowledge and expertise in recognizing potential hazards.

- Scenario Development

Developing realistic scenarios that challenge the normal operating conditions helps identify potential hazards that may not be evident during routine operations. CCPS HAC encourages brainstorming and creative thinking to explore various scenarios and their potential consequences.

- Expert Involvement

Involving experts from multiple disciplines, including process engineers, safety professionals, and operations personnel, brings diverse perspectives and expertise to the hazard identification process, enhancing its comprehensiveness and accuracy.

By emphasizing thorough analysis and utilizing a range of techniques, CCPS HAC ensures that potential hazards are systematically identified and understood, enabling proactive measures to be taken for risk mitigation and prevention.

Evaluation

Evaluation plays a critical role in CCPS HAC, as it enables informed decision-making and prioritization of risk mitigation strategies. This involves assessing the severity and likelihood of identified hazards to determine their potential impact and urgency.

Severity assessment considers the potential consequences of a hazard, including the extent of damage to equipment, injury to personnel, or environmental harm. Likelihood assessment evaluates the probability of a hazard occurring, taking into account factors such as operating conditions, equipment reliability, and human factors.

CCPS HAC provides guidance on structured methods for evaluating hazards, such as risk matrices and layers of protection analysis. These tools help organizations systematically assess and rank hazards based on their severity and likelihood, enabling them to focus resources on mitigating the most critical risks.

Effective evaluation is crucial for optimizing risk management and resource allocation. By accurately assessing the severity and likelihood of hazards, organizations can prioritize their efforts, implement targeted control measures, and make informed decisions to prevent or minimize the impact of potential incidents.

Mitigation

Mitigation is a crucial component of CCPS HAC, as it involves developing and implementing measures to reduce the risks associated with identified hazards. This proactive approach is essential for preventing incidents and safeguarding personnel, assets, and the environment.

CCPS HAC provides a structured framework for hazard mitigation, emphasizing the following key elements:

- Hazard Elimination: Identifying and eliminating hazards at the source, whenever possible, is the most effective mitigation strategy.

- Risk Reduction: Implementing measures to reduce the likelihood and/or severity of hazards that cannot be eliminated.

- Control Implementation: Establishing and maintaining effective controls, such as engineering safeguards, administrative procedures, and personal protective equipment, to minimize the impact of hazards.

- Emergency Preparedness: Developing plans and procedures for responding to potential incidents, including training and drills.

By emphasizing mitigation, CCPS HAC empowers organizations to take proactive steps towards risk reduction. Through systematic hazard identification, evaluation, and mitigation, organizations can enhance process safety, prevent incidents, and ensure the well-being of their employees, communities, and the environment.

Control

Control is a critical component of CCPS HAC, as it involves establishing and maintaining effective safeguards to prevent or minimize the impact of hazards. This proactive approach is essential for preventing incidents and safeguarding personnel, assets, and the environment.

CCPS HAC emphasizes the importance of implementing multiple layers of control to reduce risks associated with hazards. These controls can include:

- Engineering Controls: Physical measures, such as safety interlocks, pressure relief valves, and containment systems, are designed to prevent or mitigate hazards at the source.

- Administrative Controls: Policies, procedures, and work instructions provide clear guidance for safe operations and maintenance.

- Personal Protective Equipment (PPE): Protective clothing, respirators, and other equipment help protect individuals from exposure to hazards.

By establishing and maintaining effective controls, organizations can minimize the likelihood and severity of incidents, ensuring the safety of their employees and the integrity of their operations.

For instance, in the chemical industry, CCPS HAC has been instrumental in promoting the use of inherently safer design principles to reduce hazards and the need for complex controls. By incorporating safety considerations into the design phase, organizations can create processes that are less susceptible to incidents and.

Overall, the connection between Control and CCPS HAC is vital for enhancing process safety and preventing incidents. Through the systematic identification, evaluation, and control of hazards, organizations can create a safer work environment and protect their stakeholders.

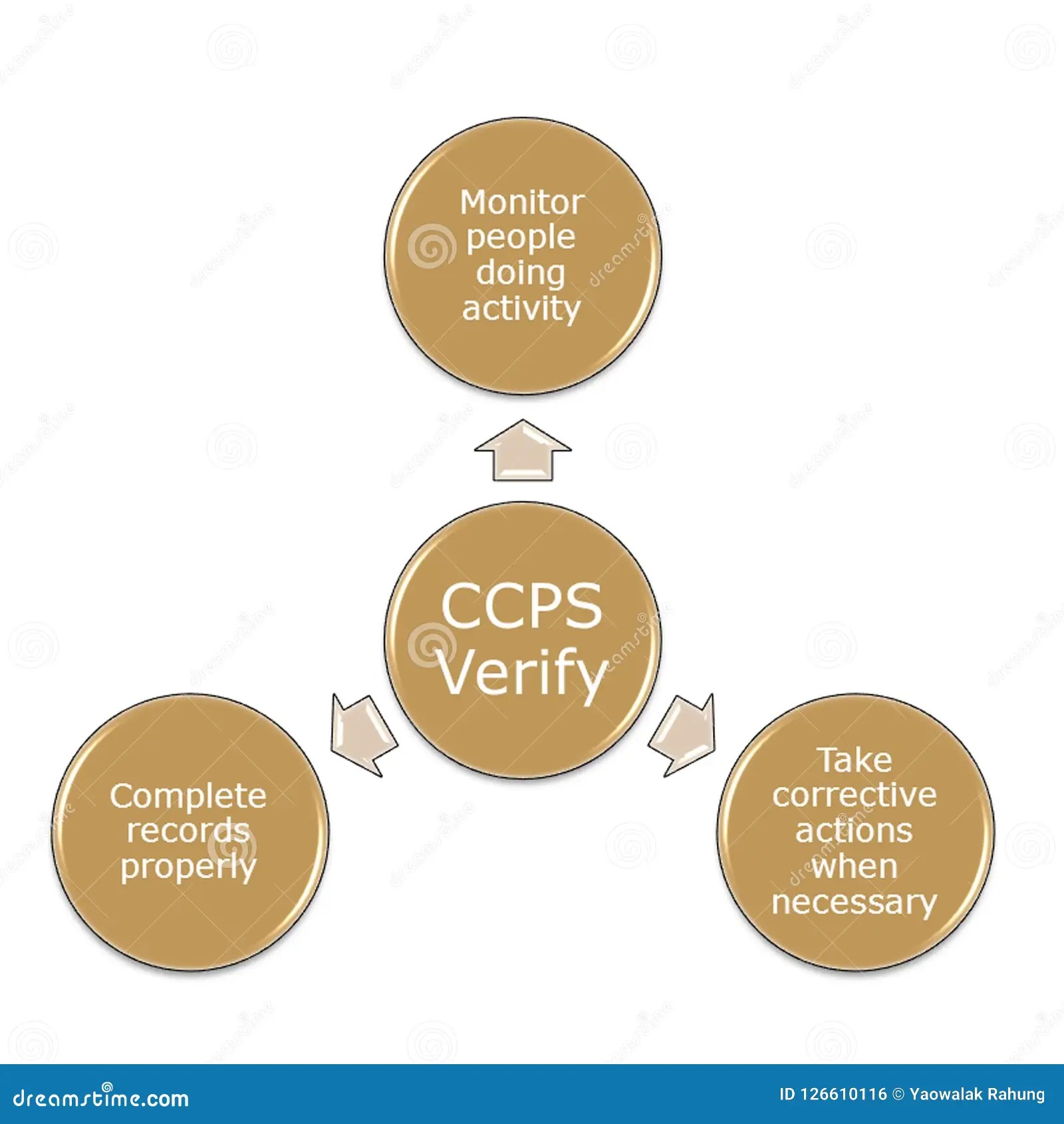

Monitoring

Monitoring is a crucial component of CCPS HAC, as it ensures the ongoing effectiveness of hazard controls and risk mitigation strategies. Regular review and update of HAC measures are essential to adapt to changing conditions, advancements in technology, and evolving industry best practices.

CCPS HAC emphasizes the importance of establishing a systematic monitoring program that includes:

- Performance Tracking: Regularly monitoring the performance of hazard controls and risk mitigation measures to identify any deviations or areas for improvement.

- Incident Investigation: Thoroughly investigating incidents and near misses to identify root causes and implement corrective actions to prevent recurrence.

- Management of Change: Reviewing and assessing the impact of process changes, new equipment, or modifications to operating procedures on hazard controls and risk mitigation measures.

- Employee Feedback: Regularly soliciting feedback from employees on the effectiveness of hazard controls and risk mitigation measures, as they often have valuable insights and observations from their daily work.

By implementing a robust monitoring program, organizations can proactively identify and address any weaknesses or gaps in their HAC measures, ensuring that they remain effective in preventing incidents and safeguarding personnel, assets, and the environment.

For example, in the oil and gas industry, CCPS HAC has been instrumental in promoting the use of monitoring technologies, such as real-time sensors and data analytics, to continuously monitor process parameters and identify potential hazards. By leveraging these technologies, organizations can improve the effectiveness of their hazard controls and respond quickly to any deviations from normal operating conditions.

Overall, the connection between Monitoring and CCPS HAC is critical for maintaining a high level of process safety and preventing incidents. Through regular review, update, and improvement of HAC measures, organizations can ensure that their risk mitigation strategies remain effective and aligned with the evolving needs of their operations.

Communication

Effective communication is a critical aspect of CCPS HAC, as it ensures that hazard control measures and risk mitigation strategies are understood, implemented, and maintained throughout the organization. By sharing HAC findings and recommendations across departments, teams, and levels of the organization, organizations can promote awareness, foster collaboration, and enhance process safety.

- Transparency and Information Sharing

Open and transparent communication of HAC findings and recommendations is essential for building trust and ensuring that all stakeholders have a clear understanding of the hazards and risks associated with their operations. Sharing HAC documentation, reports, and risk assessments across the organization allows for informed decision-making and promotes a shared responsibility for process safety.

- Collaboration and Knowledge Transfer

Regular communication and collaboration among different departments and teams, such as operations, maintenance, engineering, and safety, is crucial for effective HAC implementation. Sharing HAC findings and recommendations facilitates knowledge transfer, promotes cross-functional learning, and ensures that all personnel have the necessary information to perform their jobs safely.

- Employee Involvement and Feedback

Actively involving employees in the HAC process and soliciting their feedback is essential for ensuring that hazard controls and risk mitigation measures are practical and effective. By communicating HAC findings and recommendations to employees and encouraging their input, organizations can leverage their frontline experience and insights to improve process safety.

- External Communication and Stakeholder Engagement

In certain industries, communicating HAC findings and recommendations with external stakeholders, such as contractors, regulators, and the community, may be necessary to ensure transparency, build trust, and demonstrate commitment to process safety. Effective external communication can also facilitate collaboration and information exchange, enhancing overall safety performance.

By fostering open communication, collaboration, and knowledge sharing, organizations can create a culture of safety awareness and responsibility, empowering employees at all levels to contribute to the prevention of incidents and the protection of personnel, assets, and the environment.

Continuous Improvement

Continuous improvement is a fundamental principle of CCPS HAC, as it recognizes that process safety is an ongoing journey that requires regular evaluation and enhancement to keep pace with changing conditions and industry best practices. By embracing continuous improvement, organizations can proactively identify and address potential hazards, mitigate risks, and enhance overall process safety.

Regular evaluation of HAC processes involves reviewing their effectiveness, identifying areas for improvement, and implementing necessary changes. This may include updating risk assessments, revising procedures, and incorporating new technologies or industry standards. By continuously evaluating their HAC processes, organizations can ensure that they remain aligned with the latest safety knowledge and best practices.

HAC processes should also be adaptable to changing conditions, such as new or modified equipment, changes in raw materials, or evolving regulatory requirements. Continuous improvement enables organizations to swiftly respond to these changes and update their HAC measures accordingly, minimizing the risk of incidents and maintaining a high level of process safety.

For example, in the manufacturing industry, CCPS HAC has been instrumental in promoting the adoption of inherently safer design principles. Through continuous improvement, organizations have implemented safer technologies, redesigned processes, and optimized operating conditions to reduce hazards and the need for complex controls.

In conclusion, continuous improvement is a vital component of CCPS HAC, driving organizations to regularly evaluate and enhance their hazard controls and risk mitigation strategies. By embracing continuous improvement, organizations can adapt to changing conditions, incorporate industry best practices, and maintain a proactive approach to process safety, ultimately preventing incidents and safeguarding personnel, assets, and the environment.

Frequently Asked Questions about CCPS HAC

This section addresses common questions and misconceptions about CCPS HAC, providing concise and informative answers to enhance understanding and clarify its significance in process safety.

Question 1: What are the key benefits of implementing CCPS HAC?

Answer: CCPS HAC offers numerous benefits, including the identification and mitigation of hazards, reduction of risks, improved compliance with safety regulations, enhanced process safety culture, and ultimately the prevention of incidents and accidents, safeguarding personnel, assets, and the environment.

Question 2: How does CCPS HAC differ from traditional safety management approaches?

Answer: CCPS HAC adopts a systematic and comprehensive approach to hazard identification, evaluation, and control, distinguishing it from traditional methods. It emphasizes proactive risk management, involves cross-functional collaboration, and promotes continuous improvement, resulting in a more robust and effective safety management system.

In summary, CCPS HAC serves as a valuable tool for organizations seeking to enhance their process safety performance. Its systematic approach, focus on hazard control, and commitment to continuous improvement empower organizations to create safer work environments and prevent incidents, safeguarding their stakeholders and the communities they operate in.

Conclusion

In conclusion, CCPS HAC has emerged as a pivotal framework for hazard identification, evaluation, and control in chemical process safety. Its systematic approach empowers organizations to proactively identify and mitigate risks, prevent incidents, and enhance overall safety performance.

The adoption of CCPS HAC principles enables organizations to establish a culture of safety awareness and accountability, where all stakeholders actively participate in recognizing and addressing potential hazards. By continuously evaluating and improving their HAC processes, organizations can adapt to changing conditions, incorporate industry best practices, and maintain a proactive approach to process safety.

The widespread implementation of CCPS HAC has significantly contributed to the reduction of incidents and accidents in the chemical process industry. Its emphasis on hazard control, risk mitigation, and continuous improvement has led to safer work environments, protected personnel and assets, and minimized environmental impact.

As the chemical process industry continues to evolve, CCPS HAC will remain a cornerstone of process safety management. By embracing its principles and leveraging its systematic approach, organizations can enhance their safety performance, protect their stakeholders, and contribute to a more sustainable and resilient industry.

Also Read

Article Recommendations

ncG1vNJzZmivp6x7tMHRr6CvmZynsrS71KuanqtemLyue8alppuZnKOyuL%2BQaJqcqKNitaKvjaGrpqQ%3D